Revolutionizing Metal Fabrication with Advanced Machinery

Introduction

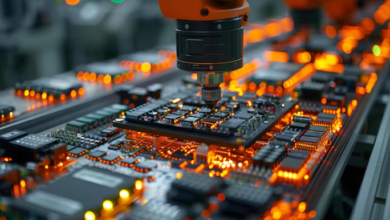

The metal fabrication industry has undergone significant transformation over the past few decades, driven by advancements in automation and precision machinery. Among these innovations, industrial press brakes have become indispensable for manufacturers who require accuracy, consistency, and efficiency in their operations. In particular, industrial series cnc press brakes have gained prominence for their ability to combine computer numerical control (CNC) technology with robust mechanical construction, enabling precise bending of sheet metal across a wide range of industries. From automotive and aerospace to construction and heavy machinery, these machines have redefined how manufacturers approach metal forming.

What Sets Industrial Press Brakes Apart

Industrial press brakes differ from traditional machines due to their automated features, durable design, and versatility. While older manual or hydraulic press brakes require repeated setups for different bend angles or complex operations, industrial series cnc press brakes allow operators to program multiple bends in a single run. This reduces human error, improves consistency, and saves valuable production time.

Moreover, these machines are designed to handle heavy-duty materials and larger sheet sizes, making them suitable for high-volume industrial production. The integration of CNC systems allows for precision that manual machines cannot match, enabling manufacturers to meet strict tolerance requirements in sectors such as aerospace or automotive parts production.

Key Features of Industrial Series CNC Press Brakes

CNC Control System

The heart of an industrial series cnc press brakes is its control system. This interface allows operators to program precise bend angles, material thicknesses, and sequence steps for complex operations. Operators can save programs for repeated production runs, ensuring consistency across batches.

Versatile Tooling

Industrial press brakes are compatible with a variety of punches and dies, enabling different bending profiles and accommodating various materials. Whether working with thin sheet metal or heavy-gauge steel, the appropriate tooling ensures accurate bends and high-quality finished components.

Back Gauge and Axis Control

The back gauge system plays a crucial role in positioning the sheet metal accurately for each bend. Industrial series cnc press brakes often feature multiple-axis back gauges, allowing precise control over depth, angle, and alignment. This multi-axis capability significantly reduces setup times and ensures repeatable results.

Safety Systems

Modern industrial press brakes are equipped with advanced safety features, including light curtains, safety guards, and emergency stop buttons. These systems protect operators from potential hazards during operation while maintaining productivity.

Advantages of Industrial Series CNC Press Brakes

Precision and Accuracy

CNC control ensures that each bend is executed according to exact specifications, eliminating inconsistencies that can occur with manual operation. This precision is critical for industries where small deviations can compromise product functionality or safety.

Efficiency and Productivity

By allowing complex bends in a single setup, industrial series cnc press brakes significantly reduce production time. Operators can program sequences for multiple parts, minimizing downtime between operations and increasing overall throughput.

Versatility in Applications

These machines are capable of handling a wide variety of materials and thicknesses. From aluminum and stainless steel to thicker high-strength alloys, industrial series cnc press brakes can adapt to diverse manufacturing needs without frequent tooling changes.

Reduced Material Waste

Accurate programming and consistent operation reduce errors, rework, and scrap material. Manufacturers benefit from lower costs and more sustainable production practices, as fewer materials are wasted due to misaligned or incorrect bends.

See also: Enhancing Business Efficiency With Accounting Services

Operating Industrial Press Brakes

Preparing for Operation

Proper preparation ensures safe and effective use of industrial series cnc press brakes:

- Wear appropriate personal protective equipment, including gloves, safety glasses, and steel-toed shoes.

- Verify that safety systems such as guards and light curtains are functional.

- Inspect punches, dies, and machine components for wear or damage.

Programming and Setup

CNC programming is essential for achieving consistent results:

- Input material type, thickness, and sheet dimensions into the control system.

- Define bend angles, sequence steps, and back gauge positions.

- Save programs for repeated use in future production runs.

Accurate programming minimizes human error and ensures reliable operation.

Loading and Bending

When operating the machine:

- Position the sheet metal correctly against the back gauge and secure it.

- Monitor the machine as it executes bends, ensuring all axes are aligned properly.

- For complex bends, consider incremental adjustments to maintain precision and prevent material deformation.

Proper operation ensures high-quality finished parts and reduces the risk of accidents.

Post-Operation Inspection

After bending, inspect the components for quality and accuracy:

- Measure angles and dimensions to verify adherence to specifications.

- Check for defects such as overbends, underbends, or material deformation.

- Make necessary adjustments to the CNC program or tooling for subsequent parts.

Regular inspection helps maintain consistent production quality and prevents defective parts from continuing through the manufacturing process.

Maintenance and Troubleshooting

Routine Maintenance

Maintaining industrial series cnc press brakes is essential for reliability and longevity:

- Lubricate moving parts according to manufacturer recommendations.

- Inspect punches, dies, hydraulic systems, and electrical components regularly.

- Test safety devices to ensure proper functionality.

- Calibrate the machine and CNC control system as required.

Routine maintenance prevents unexpected downtime and preserves machine performance.

Troubleshooting Common Issues

Common issues and solutions include:

- Misaligned bends: Adjust back gauge positioning or reprogram the CNC sequence.

- Inconsistent angles: Inspect tooling, verify material thickness, and recalibrate the machine.

- Hydraulic or electrical malfunctions: Check power supply, hydraulic pressure, and consult the machine’s troubleshooting guide.

Quick and effective troubleshooting minimizes delays and ensures continuous production.

Training and Best Practices

Operator Training

Proper training is essential for maximizing efficiency and safety:

- Learn the functions of all machine components and CNC programming basics.

- Understand safety protocols and emergency procedures.

- Gain hands-on experience with different materials, tooling, and bending sequences.

Well-trained operators reduce errors, enhance productivity, and maintain a safer working environment.

Safety and Documentation

A strong safety culture includes:

- Enforcing the use of personal protective equipment and safety systems.

- Regularly reviewing operating procedures and emergency protocols.

- Maintaining records of CNC programs, maintenance schedules, and inspections.

Documentation supports continuous improvement and regulatory compliance while ensuring repeatable quality.

Conclusion

Industrial press brakes, particularly industrial series cnc press brakes, have revolutionized metal fabrication by combining automation, precision, and versatility in one machine. They enable manufacturers to perform complex bends accurately, efficiently, and consistently across a wide range of applications. By understanding machine components, programming CNC sequences effectively, following strict safety protocols, and performing routine maintenance, manufacturers can maximize the benefits of these advanced machines. Industrial series cnc press brakes reduce material waste, improve productivity, and maintain high-quality standards, making them an essential tool in modern industrial metal fabrication.