Innovations in Adhesive and Film Technologies for Modern Manufacturing

The Hot Melt Adhesive & Films industry has undergone significant transformation over the past decade, driven by the demand for faster, more reliable, and versatile bonding solutions. Manufacturers across industries are looking for ways to enhance product performance, reduce waste, and streamline production processes. Among the materials making a substantial impact is TPU nonwoven fabric, a unique textile that combines flexibility, durability, and waterproof properties. Its integration with adhesives and films has opened new possibilities in sectors ranging from healthcare and textiles to footwear and industrial applications.

Understanding TPU Nonwoven Fabric

TPU nonwoven fabric, or thermoplastic polyurethane nonwoven fabric, is a material created by bonding fibers together through mechanical, thermal, or chemical means rather than traditional weaving. This results in a uniform, strong, and flexible fabric structure. The addition of TPU enhances the fabric’s natural properties by providing elasticity, waterproofing, and abrasion resistance, making it ideal for applications that require both protection and comfort.

The lightweight and breathable nature of TPU nonwoven fabric allows it to be used in products that must balance performance with user comfort. Furthermore, its compatibility with adhesives and films makes it an attractive choice for manufacturers looking to produce layered assemblies or laminated products efficiently.

Applications Across Industries

Healthcare and Medical Products

The healthcare industry has been one of the primary beneficiaries of TPU nonwoven fabric. Surgical gowns, drapes, masks, and protective covers often require materials that are both waterproof and breathable. TPU nonwoven fabric meets these requirements, and when paired with hot melt adhesives and films, it can create laminated products that provide superior protection without compromising comfort.

For example, hospital gowns bonded with adhesive films ensure that seams remain sealed against fluids, while still allowing for flexibility and movement. This combination not only enhances the safety of medical staff and patients but also TPU nonwoven fabric improves the durability of disposable medical textiles.

Textile and Apparel Industry

In the textile and apparel sector, TPU nonwoven fabric has found applications in functional garments such as rainwear, sportswear, and protective clothing. Its elasticity allows garments to move comfortably with the wearer, while its lightweight structure prevents unnecessary bulk.

By using adhesives to laminate TPU nonwoven fabric with other materials, manufacturers can produce garments that are both waterproof and breathable. This technique has been widely adopted in outdoor apparel, where performance under varying weather conditions is critical.

Footwear and Accessories

Footwear manufacturers increasingly rely on TPU nonwoven fabric for insoles, linings, and moisture-proof layers. Its combination of elasticity, durability, and water resistance ensures that shoes remain comfortable and functional under repeated stress.

The integration of TPU nonwoven fabric with adhesive films allows for multi-layered assemblies that are lightweight yet robust. This approach is particularly valuable in producing waterproof footwear, athletic shoes, and outdoor gear, enhancing both product performance and longevity.

Packaging and Industrial Applications

Beyond textiles, TPU nonwoven fabric is useful in packaging and industrial products. Its waterproof and elastic properties make it suitable for protective covers, bags, and membranes. Laminating TPU nonwoven fabric with films using hot melt adhesives adds structural integrity while maintaining flexibility.

In industrial filtration, TPU nonwoven fabrics combined with adhesive films can create durable, breathable barriers capable of withstanding harsh environments. This capability ensures reliable performance in both production and operational settings.

Advantages of TPU Nonwoven Fabric

Lightweight and Flexible

TPU nonwoven fabric is exceptionally lightweight and flexible, which makes it ideal for applications where minimal weight and comfort are important, such as apparel, medical textiles, and footwear.

Waterproof and Breathable

One of the standout features of TPU nonwoven fabric is its ability to provide waterproofing without sacrificing breathability. This makes it ideal for protective clothing, outdoor gear, and medical products that require barrier protection along with wearer comfort.

Durable and Elastic

The combination of TPU and nonwoven fibers provides excellent durability and elasticity. Products made from TPU nonwoven fabric can withstand repeated use and stretching without losing shape or performance, ensuring long-term reliability.

Compatibility with Adhesives and Films

TPU nonwoven fabric bonds effectively with a variety of adhesives and films, particularly hot melt adhesives. This allows manufacturers to produce laminated assemblies that are strong, flexible, and water-resistant, making it suitable for a wide range of industrial applications.

See also: Low Deposit Home Loans for Budget-Conscious Homebuyers

Best Practices for Using TPU Nonwoven Fabric

Surface Preparation

Before bonding, it is essential to prepare the surface of TPU nonwoven fabric properly. The material should be free from dust, oils, or chemical residues. Proper surface preparation ensures strong adhesion and consistent product quality.

Temperature and Pressure Control

When using hot melt adhesives with TPU nonwoven fabric, controlling temperature and application pressure is critical. Excessive heat can damage the fabric, while insufficient heat can result in weak bonds. Following manufacturer guidelines ensures optimal adhesion and durability.

Lamination and Layering

TPU nonwoven fabric can be laminated with films or other fabrics to enhance product performance. Ensuring proper alignment, even adhesive distribution, and tension control during lamination results in durable, flexible, and high-quality finished products.

Sustainability Considerations

Many modern adhesives used with TPU nonwoven fabric are solvent-free, reducing environmental impact. Precise adhesive application minimizes material waste, and the lightweight nature of TPU nonwoven fabric contributes to energy savings during production and transportation.

Innovations and Industry Trends

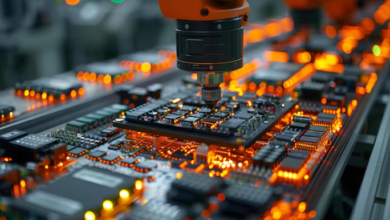

The Hot Melt Adhesive & Films industry continues to evolve, with innovations in adhesive formulations, application methods, and automation technologies. New web-based laminating equipment allows manufacturers to bond TPU nonwoven fabric at high speeds while maintaining consistent quality.

Research is also focused on recyclable and bio-based TPU materials, which align with growing sustainability goals in the manufacturing sector. These advancements are enabling the production of high-performance, eco-friendly products without compromising efficiency or quality.

Conclusion

TPU nonwoven fabric has established itself as a versatile and high-performance material in the Hot Melt Adhesive & Films industry. Its combination of flexibility, waterproofing, and durability makes it suitable for applications across healthcare, textiles, footwear, and industrial products.

When paired with adhesives and films, TPU nonwoven fabric enables the creation of laminated and layered assemblies that are both functional and reliable. By following best practices in surface preparation, temperature control, and lamination, manufacturers can maximize the benefits of this material while ensuring production efficiency and sustainability.

As innovations continue to advance in adhesive technology, TPU nonwoven fabric will play an increasingly important role in producing high-quality, durable, and environmentally responsible products for modern manufacturing.