The Role of Precision in Modern Manufacturing

In today’s fast-paced industrial landscape, the demand for durable, precise, and high-performance components continues to grow. Industries such as automotive, aerospace, industrial machinery, electronics, and even consumer products require parts that meet exacting standards to ensure reliability, efficiency, and safety. One of the most effective ways to achieve these results is through CNC machining of steel components. The production of custom machined metal parts allows manufacturers to meet complex specifications while maintaining consistency and quality across large production runs.

Understanding CNC Machining of Steel

CNC, or Computer Numerical Control, machining is a manufacturing process that uses pre-programmed software to control machine tools in removing material from a workpiece. This process enables the creation of highly complex geometries and ensures precise dimensions, which are often unattainable through manual methods.

Steel, as a material, is favored for its strength, durability, and versatility. When combined with CNC technology, it allows the production custom machined metal parts of custom machined metal parts that can withstand extreme operating conditions, high pressure, and repeated stress. The combination of material and technology ensures that every component meets industry standards and performs reliably in its intended application.

Advantages of Custom Machined Metal Parts

Precision and Accuracy

Custom machined metal parts provide unmatched precision. The CNC process ensures tight tolerances and consistent dimensions, which is crucial for assemblies that must function seamlessly. This precision minimizes errors in the final product, reducing the risk of failure and increasing overall reliability.

Flexibility in Design

CNC machining allows manufacturers to produce components of varying shapes, sizes, and complexities. From simple shafts and brackets to intricate gears and housings, custom machined metal parts accommodate highly specialized designs, enabling engineers to innovate without limitations.

Durability and Strength

Steel components produced through CNC machining maintain structural integrity under high loads, extreme temperatures, and repetitive stress. This durability makes them ideal for automotive engines, aerospace assemblies, and industrial machinery where performance is critical.

Consistency Across Production

CNC technology ensures repeatable results. Once a program is set, the machine can produce identical custom machined metal parts across hundreds or thousands of units. This level of consistency is vital for high-volume production and maintaining quality control standards.

Cost Efficiency

Although CNC machining involves initial investments in software, machines, and programming, it reduces material waste, minimizes labor costs, and allows for rapid production cycles. Over time, these efficiencies translate into significant cost savings for manufacturers.

Applications Across Industries

Custom machined metal parts are used in a variety of sectors due to their precision, strength, and adaptability.

Automotive

In the automotive industry, custom machined metal parts are essential for engine components, transmission systems, suspension elements, and structural supports. High precision ensures that these parts function effectively under the stress of daily operation, while steel’s strength enhances vehicle durability.

Aerospace

The aerospace sector requires components that are lightweight yet strong, precise, and reliable. Custom machined metal parts are used in landing gear, structural frameworks, control systems, and engine components, providing performance that meets stringent safety standards.

Industrial Machinery

Machined steel components are vital for industrial equipment such as pumps, valves, gears, and shafts. These parts must endure heavy loads and repetitive operation, maintaining dimensional accuracy and operational efficiency over time.

Electronics

In electronics, steel components serve as structural supports, housings, and protective enclosures. Custom machined metal parts ensure that sensitive equipment is shielded while maintaining mechanical stability and thermal management.

Consumer Products

From household appliances to recreational equipment, machined steel components enhance the durability, reliability, and aesthetic appeal of consumer goods. The ability to create intricate designs and finishes improves functionality and user experience.

See also: Low Deposit Home Loans for Budget-Conscious Homebuyers

The CNC Machining Process

Producing custom machined metal parts involves a series of detailed steps to guarantee quality and precision:

- Design and Programming: Engineers develop CAD (Computer-Aided Design) models and translate them into CNC programs using CAM (Computer-Aided Manufacturing) software.

- Material Selection: Steel is chosen based on mechanical properties, corrosion resistance, and application requirements.

- Machining Operations: CNC machines perform operations such as milling, turning, drilling, and grinding to remove material and shape the component.

- Finishing Processes: Components may undergo deburring, polishing, heat treatment, or coating to enhance performance, durability, and aesthetics.

- Quality Inspection: Thorough inspections, including dimensional measurement, hardness testing, and visual examination, ensure each custom machined metal part meets the required specifications.

Quality Assurance in CNC Machining

Quality control is essential in the production of custom machined metal parts. Leading manufacturers employ techniques such as coordinate measuring machines (CMM), optical inspection, and metallurgical testing to detect defects early. Consistent monitoring guarantees that each batch of components maintains high standards of precision, strength, and functionality.

Technological Advancements

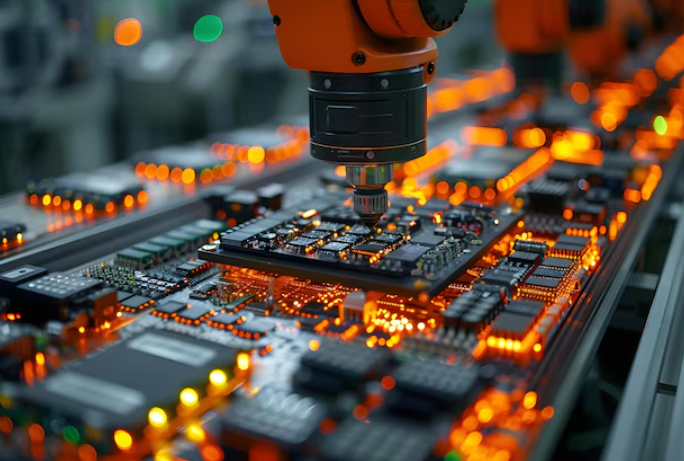

The CNC machining industry continues to evolve with innovations that enhance precision, efficiency, and design flexibility:

- Multi-axis CNC machines: Enable simultaneous operations, allowing complex parts to be produced with fewer setups.

- Advanced steel alloys: Provide improved wear resistance, strength, and corrosion protection.

- Automation and robotics: Increase productivity, reduce human error, and enhance safety.

- Simulation and optimization software: Refines tool paths and machining parameters, improving efficiency and minimizing errors.

Sustainability in Machined Metal Production

Sustainability is an increasingly important consideration in manufacturing. CNC machining reduces material waste through precise cutting, while steel is highly recyclable without losing its mechanical properties. Energy-efficient CNC machines further minimize environmental impact, ensuring that production of custom machined metal parts is both environmentally responsible and economically viable.

Future Outlook

The demand for custom machined metal parts is expected to grow as industries seek reliable, durable, and high-precision components. Advancements in CNC technology, software optimization, and material science will allow manufacturers to produce parts more efficiently, with greater flexibility and consistent quality. These innovations will continue to support industries that rely on precision-engineered components to maintain safety, performance, and competitive advantage.

Conclusion

CNC machining of steel parts has revolutionized modern manufacturing by combining precision, efficiency, and durability. Custom machined metal parts serve critical roles across automotive, aerospace, industrial machinery, electronics, and consumer products, providing high-quality, reliable components that meet rigorous standards.

By leveraging advanced CNC technology, skilled engineering, and rigorous quality control, manufacturers can produce components that are both functionally superior and cost-effective. As CNC machining continues to evolve, the ability to create complex, durable, and precise custom machined metal parts will remain essential to supporting innovation and growth across multiple industries.