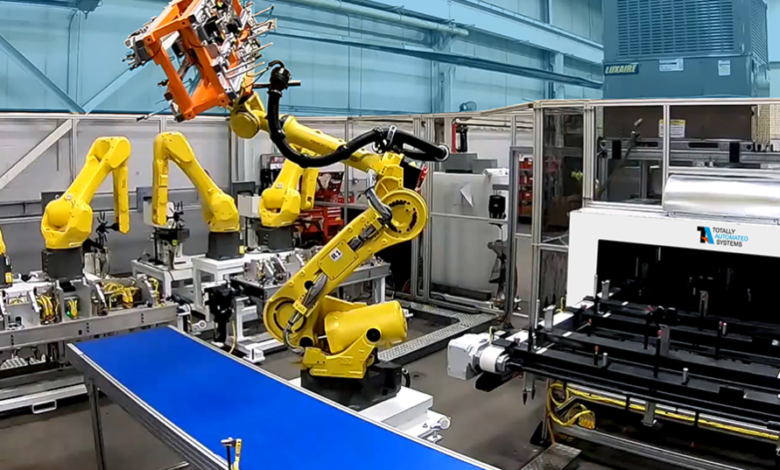

Advancing Material Handling With Innovative Solutions

Introduction

In modern manufacturing and logistics, the efficiency of material handling systems is critical to productivity and cost management. Conveyor systems serve as the backbone of many industrial operations, facilitating smooth movement of goods, reducing manual labor, and maintaining consistent workflow. Working with a reliable custom conveyor roller manufacturer ensures that businesses receive high-quality, tailored solutions for their specific operational needs.

Understanding Custom Conveyor Rollers

Custom conveyor rollers are specialized components designed to meet the exact requirements of a conveyor system. Unlike standard rollers, custom solutions can be tailored in terms of size, material, and load capacity. This customization ensures optimal performance, durability, and compatibility with complex or non-standard conveyor setups.

Benefits of Custom Rollers

Investing in custom conveyor rollers offers several advantages:

- Optimized performance: Tailored rollers provide smooth operation and reduce friction.

- Extended lifespan: High-quality materials and precise manufacturing improve durability.

- Reduced maintenance: Custom solutions are built to withstand specific operational demands, minimizing downtime.

- Safety enhancements: Reliable rollers prevent accidents and material handling disruptions.

- Versatility: Adaptable to various industries, from manufacturing to food processing.

See also: Understanding Life Insurance: The Basics Every First-Time Buyer Should Know

Key Features of High-Quality Custom Rollers

A reputable custom conveyor roller manufacturer incorporates several critical features:

- Durable materials: Steel, stainless steel, or reinforced polymers suitable for heavy or corrosive environments.

- Precision bearings: Ensure smooth rotation and consistent movement.

- Load capacity optimization: Designed to support the specific weight and size of transported items.

- Corrosion resistance: Essential for humid, chemical, or outdoor environments.

- Surface finish options: For grip, hygienic standards, or wear resistance.

Industrial Applications

Custom conveyor rollers are widely used across various sectors:

- Manufacturing: Efficiently transport raw materials, parts, and finished goods.

- Warehousing and logistics: Improve speed and accuracy in automated sorting and distribution.

- Food and beverage: Ensure safe, hygienic, and smooth handling of packaged products.

- Automotive: Handle heavy components and assemblies safely and efficiently.

- Mining and bulk materials: Manage heavy loads and harsh conditions effectively.

Roller Materials and Types

Choosing the right material is crucial for operational efficiency:

- Steel rollers: Suitable for heavy-duty applications and high-load scenarios.

- Stainless steel rollers: Ideal for food-grade environments or corrosion-prone areas.

- Polymer or plastic rollers: Lightweight, corrosion-resistant, and perfect for medium loads.

- Rubber-coated rollers: Offer additional grip and cushioning for delicate items.

The material selection affects durability, load capacity, and operational efficiency.

Customization Options Offered by Manufacturers

A skilled manufacturer offers customization options that enhance system performance:

- Size and diameter: Ensures compatibility with existing conveyors.

- Bearing types: Options like ball or roller bearings influence smoothness and load handling.

- Special coatings: Improve durability, corrosion resistance, or product grip.

- Design adaptations: For curved, inclined, or modular conveyors, ensuring seamless integration.

Customized rollers improve efficiency, reduce operational interruptions, and extend the life of conveyor systems.

Maintenance and Longevity Tips

Proper maintenance ensures the longevity and reliability of custom conveyor rollers:

- Routine inspections: Detect early signs of wear, misalignment, or damage.

- Lubrication: Reduces friction, preventing premature bearing failure.

- Cleaning: Removes debris that could obstruct movement or cause uneven wear.

- Timely replacement: Avoids unexpected downtime and maintains productivity.

Technological Advancements

Modern conveyor systems are increasingly incorporating advanced features:

- Automation integration: Rollers designed for automated systems with monitoring capabilities.

- Eco-friendly materials: Sustainable options reduce environmental impact.

- Advanced coatings: Enhance wear resistance and longevity in harsh conditions.

- Modular designs: Simplify replacements and adapt to changing production needs.

Conclusion

Collaborating with a reputable custom conveyor roller manufacturer allows businesses to enhance the efficiency, durability, and safety of their material handling systems. High-quality, tailored rollers ensure smooth operation, reduce maintenance costs, and improve overall productivity across various industries. Investing in custom solutions is a strategic approach to maintaining a competitive edge in modern industrial operations.