How to Install a Digital Pressure Regulator

What you will need

- A digital pressure regulator

- Wrenches that fit the pipes

- Thread tape or pipe sealant

- Tubing or pipe that matches your system

- A screwdriver

- Safety glasses

Find a safe place

Choose a flat spot near the equipment that needs steady air or gas. Keep the regulator away from heat and water, and make sure you can reach the display and buttons.

Turn off the supply

Close the main valve or turn off the air or gas source and let the system lose pressure. Press the machine controls to release any remaining pressure. This step keeps you safe.

See also: Low Deposit Home Loans for Budget-Conscious Homebuyers

Remove the old device

If you change an old regulator, loosen the fittings with a wrench by turning them counterclockwise. Carefully remove the old regulator. Then, check the pipe threads for any damage and wipe them clean with a cloth.

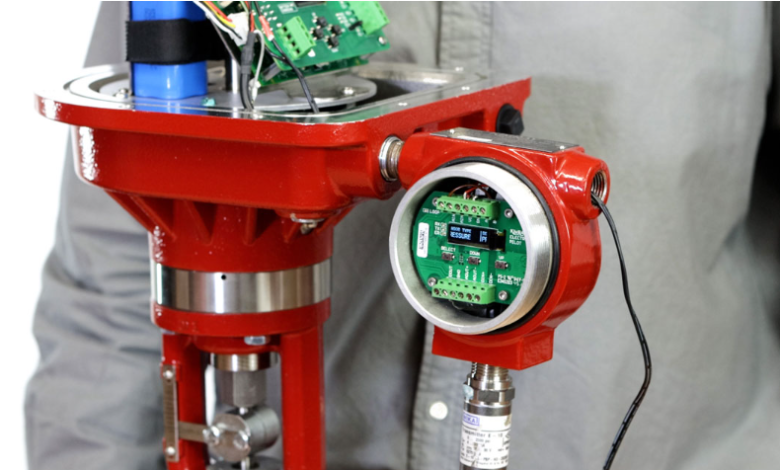

Fit the new regulator

Wrap the thread tape around the pipe end three times. Put the tape the same way the threads turn, so it does not unwrap when you screw the regulator on. Screw the digital pressure regulator on by hand and tighten with a wrench until snug. Do not over-tighten.

Connect the tubing or pipe

Connect the outlet tubing to the regulator’s output port securely. Either push it in firmly or tighten the fitting, depending on the connection type. If you notice any leaks, gently tighten them a bit more. Only use a small wrench on the nut if necessary. Make sure the tubing stays straight and isn’t bent.

Power and wires

In case your regulator requires power, connect it to the correct voltage source and follow the manual. If the device possesses a socket, insert it and push it in until a click is heard. Store the wires in such a way that they will not fray on sharp surfaces.

Turn on the supply slowly

Gradually open the main valve and observe the display screen as air or gas is introduced to the regulator. If an error occurs on the display, shut the valve immediately and inspect all linkages. Secure any loose attachments before attempting to retry.

Set the pressure

Use the up and down buttons to pick the pressure you want. Start low and move up to the target. Wait a few seconds after each change. The regulator will settle and show a stable number.

Test for leaks

Put soapy water on joints and fittings. If you notice any bubbles, it means there is a leakage. So, tighten gently and test again. No bubbles mean no leak.

Quick safety check

Make sure the display reads the pressure range you want. Check that the regulator stays steady when the machine runs. If the pressure drops or rises up so turn off the supply right away and check all the connections again.

When to call a professional

If the regulator keeps showing errors, makes unusual noises, or if you smell gas, you should immediately call a professional to resolve the matter. Because professionals have dedicated tools and devices to check the problems. So, don’t ever try to resolve these types of technical problems on your own.

Helpful tips for long life

- Clean the area around the regulator.

- Keep wires and tubing tidy.

- Check for leaks every month.

- If the digital pressure regulator has a filter, clean it as the manual says.

Final test and notes

Run the machine for a short time at the normal pressure. Watch how the device behaves. If it works without leaks or errors, you have finished the job. Keep the manual in a safe place in case you need it later.