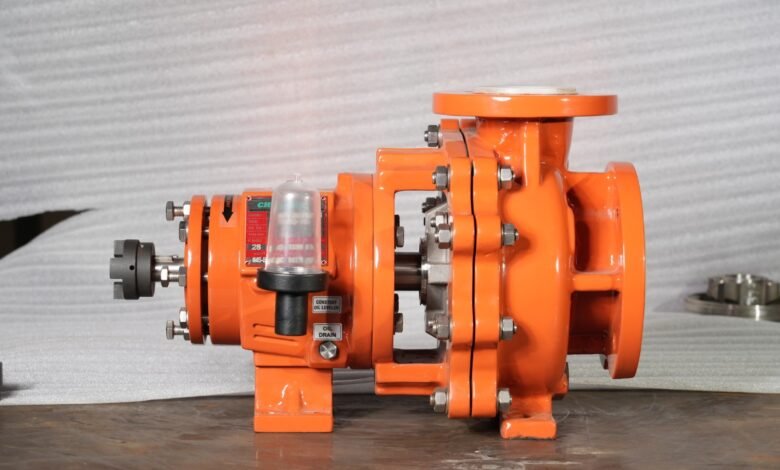

How Chemitek’s Centrifugal Pumps Can Improve Process Efficiency by 30%

Every chemical plant runs on a simple equation: efficiency in, costs out. Pumps sit at the core of this equation, moving acids, solvents, effluents, and high-value fluids around the clock. When pumps underperform, energy costs rise, downtime increases, and safety risks multiply.

This is where Chemitek’s centrifugal pumps bring real change. They are not just about moving fluids. They are engineered to improve hydraulic performance, reduce waste, and sustain efficiency even in the toughest, corrosive conditions for chemical processors, which can result in up to 30% improvement in process efficiency, a direct impact on operating costs and plant reliability.

Precision Engineering in Chemitek Pumps

Efficiency doesn’t come by chance; it’s engineered into every component. Chemitek’s centrifugal pumps are built with precision casting, advanced flow modeling, and rigorous testing. This ensures that every drop of energy is used to move fluid—not wasted in turbulence or vibration.

Optimized Impeller Geometry

- Precision-Cast Impellers: Unlike sand-cast designs, Chemitek’s investment-cast impellers have tighter tolerances. This reduces micro-gaps that create turbulence.

- Smooth Hydraulic Channels: Carefully polished surfaces prevent eddy formation, which robs pumps of efficiency.

- Hydraulic Balance: Even load distribution across blades means reduced vibration and longer bearing life.

Plant-Level Benefit: Less wasted energy equals lower operating costs. Pumps run smoother, extending seal and bearing life.

Best Efficiency Point (BEP) Alignment

- Right-Sized Pumps: Chemitek designs pumps to operate close to their BEP, the “sweet spot” of efficiency.

- Stable Pressure & Flow: This prevents cavitation, which not only damages impellers but also lowers efficiency.

- Consistent Performance: Pumps maintain flow rates even as system pressures fluctuate.

Plant-Level Benefit: Operators see fewer pressure drops, lower energy spikes, and steady solvent transfer performance over years of operation.

Material Advantage for Acidic and Corrosive Media

Design is only half the story. In chemical processing, material compatibility is the line between efficiency and failure. Many pumps lose efficiency not because of poor hydraulics but because corrosion silently degrades flow surfaces. Chemitek’s strength lies in pairing precision engineering with chemistry-specific material choices.

Non-Metallic Linings (PFA, PVDF)

- Chemical Immunity: Resistant to strong acids like hydrochloric, sulfuric, and nitric.

- No Pitting or Crevice Corrosion: Linings protect surfaces where acids usually attack metal.

- Long-Term Efficiency: Smooth polymer surfaces maintain hydraulic performance, even after years of acid duty.

Plant-Level Benefit: Less frequent replacements and no unexpected drops in flow rate caused by corroded channels.

High-Grade Alloys for Extreme Conditions

- Duplex & Super Duplex Steels: Designed for chloride-heavy environments like desalination or fertilizer units.

- 316L Stainless Steel: Ideal for pharmaceutical plants where hygiene and corrosion resistance are equally critical.

- Thermal & Mechanical Endurance: Chemitek alloys withstand both high temperature and corrosive attack simultaneously.

Plant-Level Benefit: With alloys tailored to the exact solvent, plants avoid sudden efficiency loss, contamination risks, and premature pump failures.

Key Point for Plants: Efficiency isn’t just about how a pump is designed it’s about whether it can stay efficient in real chemical environments. Chemitek ensures that with acid-proof linings and alloys, pumps run at peak efficiency long after generic pumps have failed.

Reducing Energy Consumption by 30%

Energy is the largest invisible cost in pumping systems. Corroded impellers, misaligned hydraulics, or oversized pumps make energy bills soar. Chemitek focuses directly on lowering kWh consumption per unit of fluid transferred.

Case Efficiency Example

| Pump Setup | Energy Use per Year (kWh) | Notes |

| Generic pump, corroded impeller | 120,000 | Frequent pitting increases turbulence |

| Chemitek pump, optimized design | 84,000 | 30% less energy through stable hydraulics |

- A 5–10% design gain compounds into 30% lifecycle savings.

- Plants see direct cost reductions and meet energy compliance mandates.

Smarter Monitoring for Continuous Performance

Chemitek pumps don’t stop at physical design. They are designed for smarter operations through condition monitoring.

IoT Sensors and Real-Time Data

- Track vibration, flow rate, and impeller wear continuously.

- Identify early-stage corrosion or cavitation events.

Predictive Analytics Integration

- AI models forecast failures weeks in advance.

- Operators plan maintenance during scheduled shutdowns, not emergencies.

Impact: Predictable performance, lower downtime, and pumps that always run at efficiency sweet spots.

Industry Applications Where Chemitek Pumps Prove Efficiency

Chemitek pumps aren’t built as one-size-fits-all units. They are tailored for industry-specific needs.

Chemical & Pharma

- Fluids: acetone, methanol, acetonitrile.

- Risk: pitting and surface attack.

- Chemitek solution: PFA/PVDF linings, SS316L for pharma hygiene.

Fertilizers & Dyes

- Fluids: acidic and bleaching agents.

- Risk: rapid corrosion rates.

- Chemitek solution: robust alloys, coated internals for durability.

Power & Thermal Plants

- Fluids: boiler treatment chemicals.

- Risk: cavitation and dissolved oxygen attack.

- Chemitek solution: cavitation-resistant designs with duplex alloys.

Wastewater & Effluents

- Fluids: chlorinated, abrasive effluents.

- Risk: erosion + corrosion.

- Chemitek solution: duplex steels, lined internals.

Across sectors, Chemitek pumps improve uptime and cut wasted energy in fluid transfer.

Lifecycle Value: Beyond Purchase Price

Buying pumps is often viewed as a one-time cost. But in chemical plants, pumps run continuously, making lifecycle economics more important than upfront pricing. Chemitek emphasizes Total Cost of Ownership (TCO) as the real metric of efficiency.

Maintenance Economics

- Investment casting: Stronger metallic components that resist wear, reducing replacement frequency.

- Thicker polymer linings: PFA and PVDF linings resist acids longer, extending service life.

- Quick spare availability: Standardized impellers, seals, and bearings are designed for fast swap-outs.

- AMC support: Predictable service costs that help plants budget accurately.

TCO Impact

Instead of just calculating purchase price, Chemitek helps clients look at:

- Energy per liter pumped (kWh/l)

- Service intervals per year

- Component replacement cycles

Over a 5–10 year horizon, savings from reduced downtime and lower energy consumption easily outweigh slightly higher capital costs.

Smarter Pumping with Condition Monitoring

Most pump issues don’t begin with catastrophic failure. They start with small inefficiencies, slight imbalance, pitting, or rising vibration—that go unnoticed until breakdown. Chemitek makes monitoring a standard feature, not an optional add-on.

- IoT sensors: Measure vibration, temperature, and flow rate continuously.

- AI analytics: Spot micro-patterns of wear before human inspection would catch them.

- SCADA integration: Operators get alerts directly on plant control systems.

Why it matters:

- Manual inspections only catch visible problems.

- With Chemitek’s monitoring, failures are flagged early.

- Emergency shutdowns are replaced by scheduled, predictable maintenance windows.

This shift from reactive to predictive maintenance is where Chemitek creates efficiency gains that most competitors cannot match.

The Future of Solvent Pumping

Efficiency isn’t static. Chemitek is investing in technologies that prepare chemical plants for tomorrow’s challenges, where sustainability and performance must go hand in hand.

- AI predictive maintenance: Already in use for high-value solvent handling, it will become standard across industries.

- Recyclable alloys and coatings: New material innovations reduce environmental impact while extending pump life.

- Solar-driven centrifugal pumps: Designed for agrochemical and rural applications, these reduce power costs while using stainless impellers for durability.

What this means for plants: adopting Chemitek pumps isn’t just a short-term decision. It’s a future-proof investment aligned with compliance and sustainability mandates.

Conclusion: Smarter Choices, Longer Pump Life

Unplanned pump failures are more than a repair cost; they threaten worker safety, disrupt production schedules, and put compliance at risk. Chemitek proves that with the right design and monitoring, pumps can run longer, safer, and cheaper.

What Chemitek Delivers

- Causes addressed: corrosion, cavitation, and chemical incompatibility.

- Impacts reduced: downtime, safety risks, and rising energy bills.

- Prevention ensured: through non-metallic designs, precision casting, and condition monitoring.

- Industries served: chemicals, pharma, fertilizers, power, wastewater, and more.

- Future-ready: with IoT, AI-driven analytics, and sustainable materials.

Corrosion and inefficiency may be unavoidable in theory, but Chemitek shows that their pace and cost can be controlled. With Chemitek’s centrifugal pumps, solvent transfer is not just about moving fluids; it’s about cutting energy waste, improving uptime, and safeguarding profitability.

Looking for centrifugal pumps that transform efficiency into measurable savings? Explore Chemitek’s portfolio and request a compatibility check today.