Benefits of CNC Swiss Machineing in Precision Manufacturing

Introduction to CNC Swiss Machineing

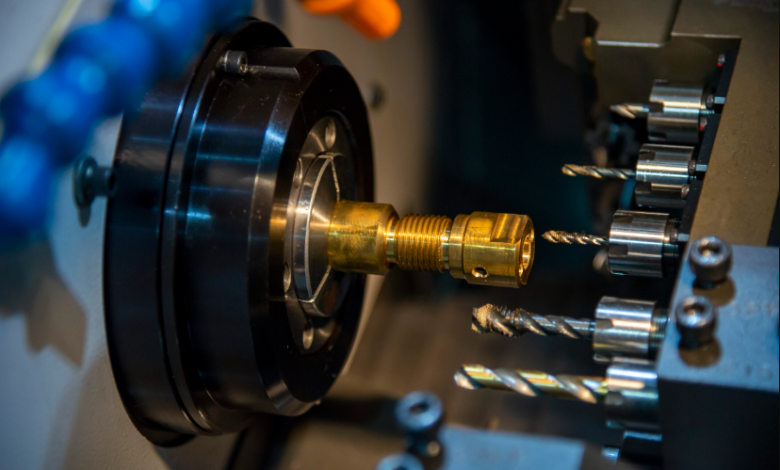

CNC swiss machineing has revolutionized precision manufacturing by offering unparalleled accuracy and efficiency. This technology is widely used in industries where tight tolerances and complex geometries are essential, including medical, aerospace, automotive, and electronics sectors. CNC swiss machineing enables the production of small and intricate components with high repeatability, reducing waste and improving overall quality.

How CNC Swiss Machineing Works

CNC swiss machineing uses a sliding headstock mechanism that allows the workpiece to be supported close to the cutting tool. This approach minimizes deflection and vibration, making it ideal for producing long, slender parts. The process is controlled by a computer, which manages all aspects of the machining operation, from tool movement to feed rates, ensuring consistent and precise results.

Sliding Headstock Mechanism

The sliding headstock design is the core of CNC swiss machineing. Unlike traditional turning methods, the material moves through the machine past the cutting tool, which remains stationary or moves minimally. This setup allows for the machining of extremely precise, small-diameter components that would be difficult to achieve otherwise.

Multi-Axis Operations

CNC swiss machineing often involves multi-axis operations, allowing the creation of complex geometries in a single setup. Multi-axis machines can perform milling, turning, drilling, and threading simultaneously, reducing production time and improving accuracy.

Tooling and Automation

Advanced tooling and automated systems enhance the efficiency of CNC swiss machineing. Automated tool changers, live tooling, and programmable spindles enable the production of multiple features on a single part without manual intervention, ensuring high productivity and consistent quality.

Advantages of CNC Swiss Machineing

Exceptional Precision

One of the most significant benefits of CNC swiss machineing is its exceptional precision. The supported workpiece design minimizes deflection, allowing manufacturers to achieve tight tolerances and consistent results for high-accuracy components.

High Efficiency

CNC swiss machineing reduces production time by combining multiple operations in one setup. Automated tooling and multi-axis capabilities allow continuous production, which is particularly useful for high-volume manufacturing.

Versatility in Materials

CNC swiss machineing can handle a wide range of materials, including stainless steel, aluminum, brass, titanium, and plastics. This versatility enables manufacturers to produce components for various industries using the same equipment.

Cost-Effective Production

While CNC swiss machineing equipment requires a significant initial investment, the reduction in material waste, labor costs, and rework leads to long-term cost savings. High precision and automation also reduce the need for secondary operations.

See also: Understanding Life Insurance Singapore

Choosing the Right CNC Swiss Machineing Provider

Expertise and Experience

Selecting a provider with experience in CNC swiss machineing is crucial. Skilled operators and engineers can optimize tool paths, material selection, and production strategies to ensure quality and efficiency.

Advanced Equipment

Modern CNC swiss machineing centers with multi-axis capabilities and automated tooling systems enable the production of complex parts with high precision. Choosing a provider with up-to-date equipment ensures consistent results and faster production.

Quality Assurance

A reliable provider implements rigorous quality control measures. Precision measurement tools and inspection protocols verify dimensions, tolerances, and surface finishes, ensuring components meet the required standards.

Timely Delivery

Providers that offer flexible scheduling and timely delivery are essential for maintaining production schedules. Efficient CNC swiss machineing services can handle urgent orders without compromising quality.

Applications of CNC Swiss Machineing

Medical Industry

CNC swiss machineing is widely used in the medical sector for producing surgical instruments, implants, and diagnostic equipment. The precision and accuracy of this technology are crucial for biocompatibility and regulatory compliance.

Aerospace Industry

In aerospace, CNC swiss machineing produces lightweight, high-strength components with tight tolerances. Engine parts, fuel system components, and structural elements benefit from the precision and reliability of this process.

Automotive Industry

CNC swiss machineing is used in automotive manufacturing for producing intricate engine components, fuel system parts, and small mechanical assemblies. High precision ensures reliability and performance under demanding conditions.

Electronics and Precision Engineering

The electronics industry relies on CNC swiss machineing for connectors, housings, and other components that require high accuracy and intricate details. This technology enables the production of small, complex parts with consistent quality.

Emerging Trends in CNC Swiss Machineing

Integration with Automation

Integrating robotics and automated systems with CNC swiss machineing increases efficiency, reduces human intervention, and ensures consistent quality, particularly for high-volume production.

Hybrid Manufacturing

Combining CNC swiss machineing with additive manufacturing allows the production of parts with complex internal features, reducing material waste and expanding design possibilities.

Sustainable Manufacturing

Energy-efficient machines and eco-friendly materials are becoming part of CNC swiss machineing practices. Sustainable production methods help reduce environmental impact while maintaining precision and efficiency.

Digital Manufacturing and Simulation

Advanced simulation and digital twin technologies allow manufacturers to optimize CNC swiss machineing processes before production, minimizing errors and improving efficiency.

Conclusion

CNC swiss machineing is a vital technology for modern precision manufacturing. Its ability to produce highly accurate, complex, and small components makes it indispensable across industries such as medical, aerospace, automotive, and electronics. By choosing a provider with advanced machinery, experienced staff, and strong quality control, manufacturers can achieve consistent results, reduce costs, and improve production efficiency. As technology continues to evolve, CNC swiss machineing remains a cornerstone of precision engineering and innovation.