How to Properly Read a Mercury Thermometer (Step-by-Step Guide)

Introduction to Mercury Thermometers

Mercury thermometers have been a cornerstone of temperature measurement for centuries, representing one of humanity’s most reliable and accurate methods for determining body temperature and environmental conditions. Despite the emergence of digital alternatives, these traditional instruments continue to hold significant value in medical settings, scientific applications, and household use due to their exceptional precision and durability.

The fundamental principle behind mercury thermometer lies in the predictable expansion and contraction of mercury in response to temperature changes. This liquid metal’s unique properties make it an ideal medium for temperature measurement, as it expands uniformly and responds quickly to thermal variations. Understanding how to properly read these instruments is essential for anyone who relies on accurate temperature measurements, whether for medical diagnosis, scientific research, or general health monitoring.

The art of reading a mercury thermometer extends beyond simply looking at where the mercury column ends. It requires an understanding of the instrument’s construction, proper handling techniques, and the ability to interpret readings accurately under various conditions. This comprehensive guide will walk you through every aspect of mercury thermometer use, ensuring you can obtain reliable and precise temperature measurements every time.

Understanding the Basic Components

A mercury thermometer consists of several critical components that work together to provide accurate temperature readings. The glass tube forms the main body of the instrument, containing a precisely calibrated bore that allows mercury to move freely in response to temperature changes. This tube is manufactured with extreme precision to ensure consistent measurements across the entire temperature range.

The mercury reservoir, located at the bottom of the thermometer, contains the liquid metal that serves as the temperature-sensing element. This bulbous section is designed to maximize surface area contact with the subject being measured, allowing for rapid thermal equilibrium. The size and shape of this reservoir directly impact the thermometer’s response time and sensitivity.

The graduated scale running along the length of the tube provides the reference points for reading temperature values. These markings are typically etched or printed with great precision, often showing both Celsius and Fahrenheit scales. The spacing between graduations varies depending on the thermometer’s intended use, with medical thermometers featuring finer divisions for greater accuracy in the human body temperature range.

The constriction point, found just above the mercury reservoir, represents one of the most ingenious aspects of mercury thermometer design. This narrow section prevents mercury from falling back into the reservoir immediately after measurement, allowing the reading to be maintained until the thermometer is deliberately reset. This feature is particularly important for medical applications where the maximum temperature reached must be preserved for accurate diagnosis.

Safety Considerations Before Use

Working with mercury thermometers requires careful attention to safety protocols due to the toxic nature of mercury. While the amount of mercury contained in a typical thermometer is relatively small, proper handling procedures must be followed to prevent exposure and contamination. Understanding these safety measures is crucial for protecting both the user and the environment.

Before handling any mercury thermometer, ensure your hands are clean and dry to maintain a secure grip and prevent contamination of the instrument. Avoid touching the mercury reservoir directly with your fingers, as oils and residues can affect the thermometer’s accuracy and potentially interfere with proper thermal contact. Always handle the thermometer by its upper stem, away from the sensitive measuring components.

The workspace where mercury thermometer readings are taken should be well-lit and free from distractions. Adequate lighting is essential for accurate reading of the mercury column, while a distraction-free environment helps prevent accidents that could result in thermometer breakage. Keep the area clear of obstacles and ensure you have a stable surface nearby where the thermometer can be safely placed when not in use.

Storage of mercury thermometers requires special consideration to prevent damage and ensure longevity. These instruments should be kept in protective cases or holders that prevent rolling and impact damage. Extreme temperatures should be avoided during storage, as they can affect the calibration and potentially damage the glass construction. Never store mercury thermometers in locations where they might be subjected to vibration or mechanical stress.

See also: Discover Your Perfect Dentist in Sea Isle City for a Healthier Smile

Preparing the Thermometer for Reading

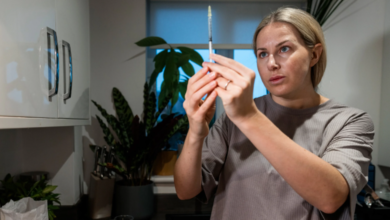

Proper preparation of a mercury thermometer is essential for obtaining accurate and reliable temperature measurements. This process begins with a thorough visual inspection of the instrument to ensure it is in good working condition and free from damage that could affect its performance. Check the glass tube for cracks, chips, or other signs of damage that could compromise the thermometer’s integrity.

The mercury column must be properly positioned before taking any measurement. If the mercury has risen above the normal starting position due to previous use or storage conditions, it must be shaken down to reset the reading. This process requires a specific technique to avoid damage while ensuring the mercury returns to its proper starting position in the reservoir.

To shake down the mercury, hold the thermometer firmly by the upper end, ensuring your grip is secure but not so tight as to risk breaking the glass. With a sharp, controlled wrist motion, snap the thermometer downward while maintaining your grip. The goal is to create enough force to drive the mercury through the constriction point back into the reservoir. This motion should be repeated several times until the mercury reading shows the lowest possible temperature on the scale.

Cleaning the thermometer before use is another critical preparation step, particularly for medical applications. The mercury reservoir and surrounding glass should be cleaned with an appropriate disinfectant solution, followed by thorough drying. This process eliminates any contaminants that could affect the accuracy of the reading or pose health risks. Always allow the thermometer to return to room temperature after cleaning before attempting to take measurements.

The Reading Process Explained

Reading a mercury thermometer accurately requires patience, proper positioning, and careful observation of the mercury column. The process begins with placing the thermometer in the appropriate position for the type of measurement being taken, whether oral, rectal, or axillary for medical applications, or in the environment for ambient temperature readings.

Once the thermometer is properly positioned, allow sufficient time for thermal equilibrium to be established. This process typically takes several minutes, depending on the temperature difference between the thermometer and the subject being measured. The mercury will gradually rise or fall until it reaches a stable position that accurately reflects the temperature. Rushing this process will result in inaccurate readings that do not represent the true temperature.

The actual reading of the mercury level requires careful observation and proper positioning of your eye relative to the thermometer scale. Hold the thermometer at eye level, ensuring the scale is clearly visible and well-illuminated. The mercury column should be viewed straight-on rather than from an angle to avoid parallax errors that can significantly affect the accuracy of the reading.

The top of the mercury column, known as the meniscus, provides the reference point for reading the temperature value. Due to the properties of mercury and its interaction with glass, this meniscus typically forms a convex shape. The correct reading is taken from the top of this curved surface, not from the sides where the mercury contacts the glass tube. This distinction is crucial for obtaining accurate measurements.

Interpreting Temperature Measurements

Accurate interpretation of mercury thermometer readings extends beyond simply noting where the mercury column ends. Understanding the scale markings, interpolating between graduations, and accounting for various factors that can influence readings are all essential skills for obtaining meaningful temperature measurements.

Most mercury thermometers feature multiple scale markings with varying degrees of precision. The major graduations typically represent whole degree increments, while smaller markings indicate fractional degrees. Medical thermometers often include markings for tenths of degrees, allowing for very precise temperature measurements crucial for medical diagnosis and monitoring.

When the mercury column falls between scale markings, interpolation becomes necessary to determine the exact temperature reading. This process involves estimating the position of the mercury top relative to the surrounding graduations. With practice, this estimation can be quite accurate, allowing for readings to a precision that exceeds the thermometer’s marked graduations.

Environmental factors can influence both the accuracy and interpretation of mercury thermometer readings. Room temperature, air circulation, and the thermal mass of surrounding objects can all affect the thermometer’s performance. Understanding these influences helps in obtaining more accurate readings and properly interpreting the results within the context of the measurement conditions.

The time factor also plays a crucial role in reading interpretation. Mercury thermometers require time to reach thermal equilibrium, and readings taken too quickly will not accurately reflect the true temperature. Conversely, leaving the thermometer in place too long may result in readings that reflect changes in the temperature being measured rather than the initial condition of interest.

Common Mistakes to Avoid

Several common errors can significantly impact the accuracy and reliability of mercury thermometer readings. Understanding these potential pitfalls and learning to avoid them is essential for anyone who relies on precise temperature measurements. These mistakes often stem from improper technique, inadequate preparation, or misunderstanding of the instrument’s operation.

One of the most frequent mistakes involves inadequate shaking down of the mercury column before use. When the mercury remains elevated from previous readings, new measurements will be artificially high, leading to incorrect conclusions about temperature conditions. Always ensure the mercury has been properly reset to its lowest position before beginning any measurement procedure.

Improper positioning of the thermometer during reading represents another common source of error. Whether taking body temperature or measuring environmental conditions, the thermometer must be positioned correctly to ensure accurate thermal contact and reading. Partial insertion, poor contact, or movement during the measurement period can all result in inaccurate readings that do not reflect the true temperature.

Reading the thermometer too quickly is a mistake that often occurs when users are impatient or unfamiliar with the time requirements for accurate measurement. Mercury thermometers need adequate time to reach thermal equilibrium, and premature readings will not accurately reflect the temperature being measured. Always allow sufficient time for the mercury to stabilize before taking a reading.

Parallax errors occur when the thermometer is not viewed from the correct angle, causing the apparent position of the mercury column to shift relative to the scale markings. This type of error can introduce significant inaccuracies in the final reading and is easily avoided by ensuring the thermometer is viewed at eye level with proper alignment.

Maintaining Your Mercury Thermometer

Proper maintenance of mercury thermometers is essential for ensuring long-term accuracy, reliability, and safety. These precision instruments require careful handling and regular attention to maintain their calibration and prevent damage that could affect their performance or pose safety risks.

Regular cleaning forms the foundation of good thermometer maintenance, particularly for instruments used in medical applications. The cleaning process should remove any residues, contaminants, or biological materials that could affect accuracy or create health hazards. Use appropriate disinfectant solutions that are compatible with glass and mercury, followed by thorough rinsing and drying.

Storage conditions play a crucial role in maintaining thermometer accuracy and preventing damage. Mercury thermometers should be stored in protective cases or holders that prevent movement and impact damage. The storage environment should be temperature-controlled and free from extreme conditions that could affect the instrument’s calibration. Avoid locations where the thermometer might be subjected to vibration, shock, or rapid temperature changes.

Periodic calibration checks help ensure that mercury thermometers continue to provide accurate readings over time. This process involves comparing the thermometer’s readings against known temperature standards or other calibrated instruments. While home users may not have access to professional calibration equipment, comparing readings between multiple thermometers can help identify instruments that may have drifted from their original accuracy.

Visual inspection should be performed regularly to identify any signs of damage or wear that could affect the thermometer’s performance. Look for cracks in the glass, damage to the scale markings, or separation of the mercury column that could indicate internal problems. Any thermometer showing signs of damage should be removed from service immediately to prevent safety hazards and inaccurate readings.

When to Replace Your Thermometer

Determining when to replace a mercury thermometer requires careful consideration of several factors including accuracy, safety, and overall condition. While these instruments are generally very durable and can provide years of reliable service, certain conditions warrant replacement to ensure continued accuracy and safety.

Physical damage represents the most obvious indication that a thermometer needs replacement. Any cracks in the glass tube, damage to the mercury reservoir, or separation of the mercury column indicates that the instrument is no longer reliable and may pose safety risks. Such damage can occur from dropping, impact, or exposure to extreme temperature changes.

Calibration drift is another factor that may necessitate replacement, particularly in applications where high accuracy is critical. Over time, mechanical stress, temperature cycling, and other factors can cause thermometers to lose their original calibration. If calibration checks reveal consistent inaccuracies that cannot be corrected, replacement becomes necessary.

The mercury column separation or fragmentation indicates internal problems that typically cannot be repaired. When mercury breaks into multiple segments within the tube, the thermometer can no longer provide accurate readings and should be replaced immediately. This condition often results from shock, vibration, or manufacturing defects.

Age-related deterioration may also warrant replacement, even in the absence of obvious damage. Very old thermometers may suffer from gradual changes in glass properties, scale marking deterioration, or other age-related issues that affect their reliability. Regular performance checks can help identify these conditions before they compromise measurement accuracy.

Alternative Temperature Measurement Methods

While mercury thermometers remain highly accurate and reliable, understanding alternative temperature measurement methods provides valuable context and options for different applications. Modern technology has introduced several alternatives that offer advantages in specific situations, though each method comes with its own strengths and limitations.

Digital electronic thermometers have become increasingly popular due to their ease of use, quick response time, and digital display that eliminates reading errors. These instruments use electronic sensors to detect temperature changes and convert them to digital readings. While convenient, they require batteries and may be less accurate than mercury thermometers in some applications.

Infrared thermometers offer non-contact temperature measurement, making them ideal for situations where physical contact is not possible or desirable. These instruments detect thermal radiation emitted by objects and convert it to temperature readings. However, they can be affected by environmental conditions and may not be suitable for all measurement applications.

Liquid-in-glass thermometers using alcohol or other liquids provide an alternative to mercury while maintaining the basic operating principle of thermal expansion. These instruments avoid the toxicity concerns associated with mercury but may have different accuracy characteristics and temperature ranges.

Thermocouple and resistance temperature detector (RTD) systems offer high accuracy and can be used in extreme conditions where glass thermometers would be impractical. These electronic systems are commonly used in industrial and scientific applications but require more complex instrumentation and calibration procedures.

Troubleshooting Common Issues

Understanding how to identify and resolve common issues with mercury thermometers can help extend their useful life and maintain measurement accuracy. Many problems that appear serious can often be resolved with proper techniques and understanding of the instrument’s operation.

Mercury column separation is one of the most common issues encountered with mercury thermometers. This condition occurs when the mercury breaks into multiple segments within the tube, preventing accurate readings. In many cases, gentle warming of the thermometer bulb while holding it vertically can help reunite the mercury segments. However, this procedure should be performed carefully to avoid overheating or damage.

Sluggish mercury response may indicate contamination or partial blockage within the tube. This condition manifests as slow mercury movement or failure to reach expected levels during temperature measurement. Cleaning the thermometer thoroughly and allowing it to reach room temperature may resolve this issue. If the problem persists, the thermometer may require professional servicing or replacement.

Scale reading difficulties can arise from worn or damaged markings, poor lighting conditions, or user technique issues. Ensuring adequate lighting and proper viewing angle often resolves reading problems. If scale markings are damaged or faded, the thermometer should be replaced to maintain accuracy.

Calibration issues may develop over time due to various factors including mechanical stress, temperature cycling, or manufacturing variations. If readings consistently differ from known standards or other calibrated instruments, the thermometer may require professional calibration or replacement.

Certified Material Testing Products (Certified MTP) is a leading supplier of construction materials testing equipment and laboratory supplies in the United States. They offer a comprehensive range of products for testing concrete, asphalt, aggregate, soil, and cement, catering to both field and laboratory applications But no matter whether they are prefered or not, the whole idea behind these tools is similar: getting a polished, shiny, and permanent effect. New to stucco or a seasoned pro, investing in good tools and learning the nuances of their use is what will get you started perfecting your craft.

Frequently Asked Questions

How long should I leave a mercury thermometer in place when taking a temperature reading?

The duration required for accurate temperature measurement depends on the specific application and conditions. For oral temperature readings, typically 3-5 minutes is sufficient for the mercury to reach thermal equilibrium. Rectal measurements may require slightly less time due to better thermal contact, while axillary (underarm) readings often need 5-7 minutes. Environmental temperature measurements may require longer periods, particularly when there is a significant temperature difference between the thermometer and the environment being measured.

What should I do if my mercury thermometer breaks?

If a mercury thermometer breaks, immediate action is required to prevent mercury exposure and contamination. First, evacuate people and pets from the area and ensure adequate ventilation. Never use a vacuum cleaner or broom to clean up mercury, as this can spread the contamination. Use a flashlight to locate all mercury droplets, then carefully collect them using an eyedropper or piece of cardboard. Place all mercury and broken glass in a sealed container and contact local environmental authorities for proper disposal instructions.

How accurate are mercury thermometers compared to digital alternatives?

Mercury thermometers are generally considered among the most accurate temperature measurement devices available, with typical accuracies of ±0.1°C when properly calibrated and used correctly. Digital thermometers can achieve similar accuracy levels but may be affected by battery condition, environmental factors, and calibration drift over time. The key advantage of mercury thermometers is their stability and consistency over long periods without requiring battery replacement or electronic calibration.

Can mercury thermometers be repaired if damaged?

Most damage to mercury thermometers cannot be economically repaired and replacement is usually the best option. Cracked glass tubes, damaged reservoirs, or mercury column separation typically indicate that the thermometer should be discarded safely and replaced. Minor issues such as dirty surfaces can often be resolved through proper cleaning procedures, but any structural damage compromises both accuracy and safety.

Are there any health risks associated with using mercury thermometers?

When used properly and kept intact, mercury thermometers pose minimal health risks. The mercury is contained within the sealed glass tube and cannot escape during normal use. However, if the thermometer breaks, mercury vapor can be released, which is toxic if inhaled. Proper handling, storage, and disposal procedures minimize these risks. Many healthcare facilities and some jurisdictions have moved away from mercury thermometers due to these safety concerns.

How should mercury thermometers be stored to maintain accuracy?

Proper storage involves keeping mercury thermometers in protective cases or holders that prevent rolling and impact damage. Store them in a temperature-controlled environment away from extreme heat, cold, or rapid temperature changes. The storage location should be dry and free from vibration or mechanical stress. Always ensure the mercury has been shaken down to its lowest position before storage to prevent permanent elevation of the baseline reading.

What temperature range can mercury thermometers measure?

The temperature range of mercury thermometers varies depending on their design and intended application. Medical thermometers typically measure from about 35°C to 42°C (95°F to 108°F), which covers the normal range of human body temperatures. Laboratory and industrial mercury thermometers can measure much wider ranges, from approximately -39°C to 357°C (-38°F to 675°F), depending on their construction and the pressure within the tube.

How do I know if my mercury thermometer needs calibration?

Signs that a mercury thermometer may need calibration include consistently reading higher or lower than other known accurate thermometers, failing to return to the same reading when exposed to the same temperature conditions, or showing gradual drift in readings over time. For critical applications, professional calibration services can verify accuracy against certified standards. Home users can perform basic checks by comparing readings with other thermometers or testing against known temperature points like ice water (0°C/32°F).

Is it legal to purchase and use mercury thermometers?

The legal status of mercury thermometers varies by jurisdiction and application. Many countries and states have restricted or banned the sale of mercury thermometers for consumer use due to environmental and health concerns. However, they may still be available for certain professional, scientific, or industrial applications. Check local regulations before purchasing or using mercury thermometers, and consider whether digital alternatives might be more appropriate for your needs.

How do environmental conditions affect mercury thermometer readings?

Environmental factors such as air temperature, humidity, air circulation, and atmospheric pressure can influence mercury thermometer readings. Rapid air movement can affect readings by cooling or heating the thermometer during measurement. High humidity may affect the rate of thermal equilibrium. For most accurate results, take measurements in stable environmental conditions and allow adequate time for the thermometer to equilibrate with the temperature being measured. Shield the thermometer from direct sunlight, drafts, and other sources of thermal disturbance during measurement.